When it comes to achieving precision surface finishes, selecting the right superfinishing products is critical. Whether you’re working with components for automotive, aerospace, medical devices, or industrial equipment, the superfinishing process can dramatically improve surface quality, extend component lifespan, and enhance performance. At Precision Surfaces International, Inc. (PSI), we understand the importance of tailoring solutions to meet the exacting demands of your applications. Here’s a guide to help you choose the right superfinishing products for your needs.

Understanding Superfinishing

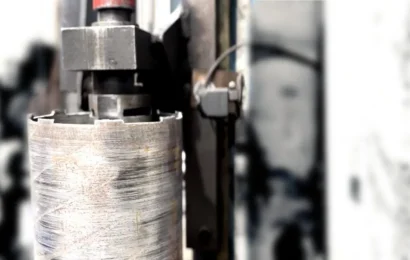

Superfinishing is a micro-abrasive process designed to refine surface geometry and remove imperfections at a microscopic level. Unlike conventional grinding or polishing, superfinishing delivers ultra-smooth surfaces with enhanced functional properties like reduced friction, improved wear resistance, and optimal load-bearing capacity.

Choosing the right superfinishing products requires an understanding of several factors, including the material, component geometry, and the desired surface finish. Let’s break down the key considerations.

Determine Your Application Requirements

Every industry and application has unique requirements for surface finish. Start by identifying:

- Surface Finish Specifications: Define the required Ra (roughness average) or Rz (average peak-to-valley height) values for your application.

- Material Type: Different materials, such as steel, aluminum, ceramics, or composites, require specific superfinishing products.

- Component Geometry: Flat surfaces, cylindrical parts, or intricate geometries demand tailored solutions for effective superfinishing.

- Functional Needs: Consider properties like reduced friction, corrosion resistance, or wear resistance that the superfinishing process must achieve.

Choose the Right Superfinishing Tools

The effectiveness of the superfinishing process heavily depends on the tools used. PSI offers a wide range of superfinishing products, including:

- Abrasive Films: These flexible films are ideal for precision applications and allow for consistent results on a variety of materials.

- Superfinishing Stones: For cylindrical or flat components, superfinishing stones deliver high precision and are available in various abrasive types, including aluminum oxide, silicon carbide, and CBN (cubic boron nitride).

- Specialized Compounds: These are perfect for achieving ultra-smooth finishes in complex geometries or high-tolerance components.

Match Abrasive Types to Your Application

The abrasive material is a critical factor in the superfinishing process. Here’s a quick guide to choosing the right type:

- Aluminum Oxide: Ideal for steels and general-purpose applications.

- Silicon Carbide: Provides a sharper cut and is excellent for non-ferrous materials like aluminum and brass.

- Diamond and CBN: Best suited for hard or brittle materials, including ceramics and hardened steel.

Optimize Your Superfinishing Parameters

Selecting the right superfinishing product also involves optimizing parameters such as:

- Grit Size: Coarse grits (lower numbers) are suitable for material removal, while fine grits (higher numbers) deliver ultra-smooth finishes.

- Bond Type: The bonding material affects the performance and wear rate of superfinishing stones. PSI offers both vitrified and resin-bonded options.

- Lubricants: Proper lubrication is essential for cooling, reducing friction, and enhancing the life of your superfinishing products.

Partner with Experts

Choosing the right superfinishing products is not a one-size-fits-all decision. By partnering with PSI, you gain access to:

- Customized Solutions: We work closely with you to develop tailored superfinishing products that meet your specific needs.

- Technical Expertise: Our team of experts provides guidance on process optimization, product selection, and troubleshooting.

- Advanced Materials: PSI uses cutting-edge materials and technologies to deliver superior performance and value.

Achieve Excellence with PSI’s Superfinishing Products

At PSI, we are committed to helping our customers achieve precision surface finishes that exceed industry standards. Our extensive product range, combined with decades of expertise, ensures that you have the tools and support necessary to optimize your superfinishing processes.

Ready to elevate your surface finishing capabilities? Contact Precision Surfaces International, Inc. today to learn more about our superfinishing products and how we can help you achieve exceptional results in your applications.