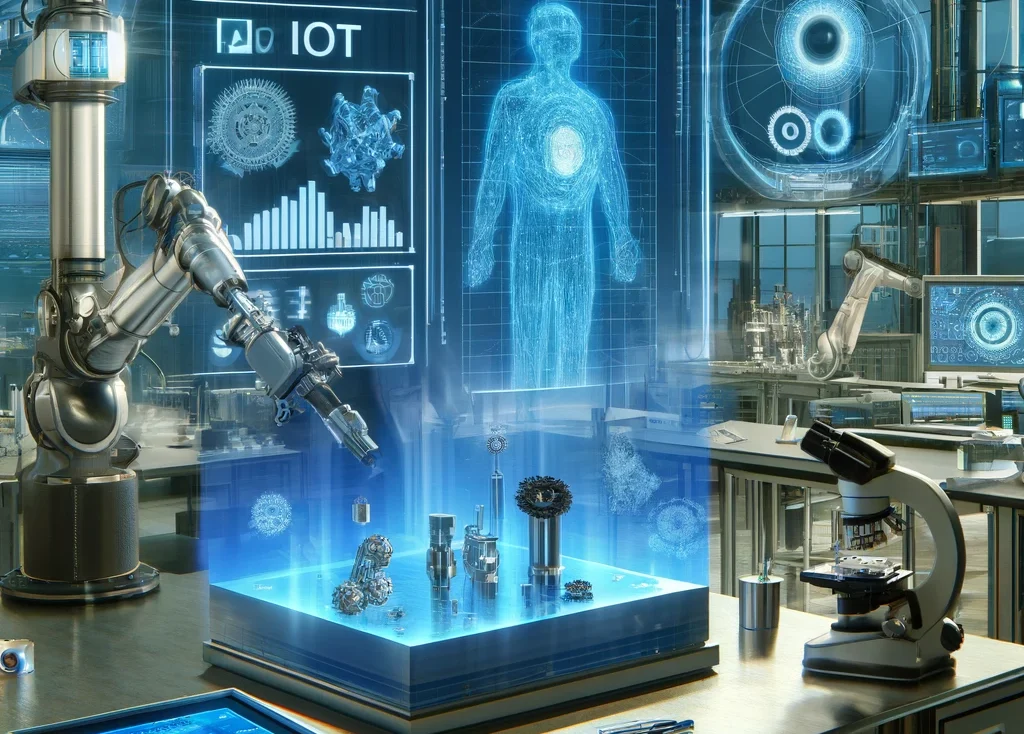

In recent years, technological advancements have dramatically transformed metallurgical analysis. Artificial Intelligence (AI), the Internet of Things (IoT), and advanced imaging tools are reshaping how materials are tested, analyzed, and optimized. These innovations are enhancing accuracy, efficiency, and predictive capabilities, leading to improved product quality and cost savings. Let’s explore how these technologies are revolutionizing metallurgical analysis.

Artificial Intelligence in Metallurgical Analysis

AI-driven systems are streamlining metallurgical analysis by automating data processing and pattern recognition. Machine learning algorithms can analyze vast datasets, identify material defects, and predict failure points with greater accuracy than traditional methods. Some key benefits include:

- Automated Defect Detection: AI-powered software can quickly assess microstructural images to detect inconsistencies and defects, reducing human error.

- Predictive Maintenance: AI helps predict potential failures in equipment used for metallurgical testing, preventing downtime and costly repairs.

- Optimized Process Control: AI algorithms continuously improve testing protocols by analyzing previous results, ensuring consistent quality.

IoT-Enabled Smart Metallurgical Labs

The IoT is integrating smart sensors and connected devices into metallurgical labs, enabling real-time monitoring and control of testing environments. This connectivity brings numerous advantages:

- Remote Monitoring: IoT sensors provide real-time updates on critical parameters such as temperature, pressure, and humidity, allowing remote access and adjustments.

- Data-Driven Decision Making: Connected systems collect and analyze performance data, leading to better insights and faster optimization of processes.

- Increased Equipment Efficiency: IoT-enabled predictive analytics ensure optimal usage of lab equipment, reducing operational costs.

Advanced Imaging Tools: Enhancing Material Analysis

High-resolution imaging techniques are transforming metallurgical analysis by providing unparalleled insights into material structures. Some notable advancements include:

- Scanning Electron Microscopy (SEM): Modern SEM technology offers ultra-high resolution imaging, allowing researchers to examine material surfaces at the nanoscale.

- X-ray Computed Tomography (XCT): XCT provides 3D imaging of internal structures, enabling non-destructive testing of components.

- Hyperspectral Imaging: This technology enhances the identification of different material compositions, improving metallurgical research and quality control.

The Future of Metallurgical Analysis

The integration of AI, IoT, and advanced imaging tools is leading to a new era of metallurgical analysis, where processes are more precise, efficient, and automated. As these technologies continue to evolve, they will further enhance material testing, reduce costs, and improve product reliability across industries.

At Precision Surfaces International, Inc. (PSI), we are committed to staying at the forefront of these advancements, providing our clients with cutting-edge solutions to meet their metallurgical analysis needs. Contact us today to learn how our expertise and technology-driven approach can benefit your industry.

For more information on our specialized abrasive solutions and testing technologies, visit our website or reach out to our expert team!